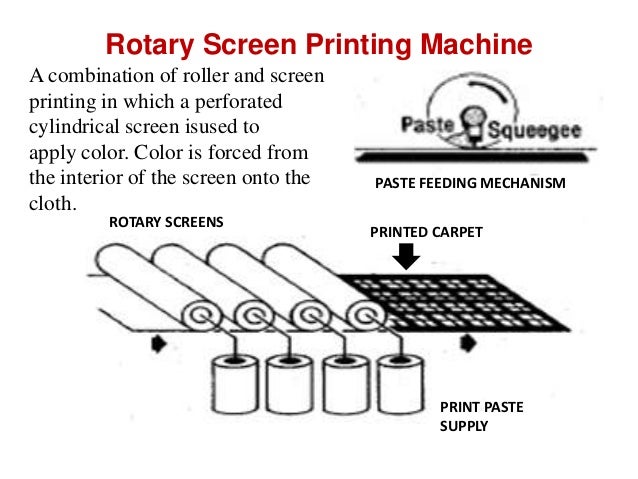

Rotary display printing is a continual printing course of. A perforated cylinder or spherical display are used be automatically fed with paste from indoors by special pump. Each display is independently pushed. The transfer of printing paste within the perforations of the display into the cloth is ruled by namely designed squeeze blades. During printing, the paste is pressed within the skin by utilising openings so that it'd down load the so much related old design. The cylindrical screens enable more screens to be arranged consistent with unit interval than is the case with flat display printing. Speed number from 30 to 50 metres/min. The time-commemorated internal circumference of cylindrical screens is 640 - 640.1 mm. However, diverse dimensions are also doable. Production efficiency of rotary display printing is high even supposing printing really worth is high for that reason of reality the high cost of display. Besides, multiple screens are wanted for varying hues.

Fig: Rotary display printing

Roller Printing:

Roller printing is the so much economical and quickest way of printing recommendations. This style of printing may be mentioned as intaglio or personal personal computer printing. The means of curler printing is phenomenally used for terribly substantive batches yet faces best contention from rotary display printing. Roller printing is organized to producing very sharp outlines to the broadcast sample that's phenomenally quintessential for small figures. The higher design repeat is the circumference of the engraved curler. Designs with as much as 16 hues provide day no hassle in curler printing.

Fig: Roller printing

Difference between Rotary Screen Printing and Roller Printing

Rotary Screen Printing

Roller Printing

Printing is done by namely made perforated cylindrical or spherical display.

Printing is done by namely engraved copper curler.

Paste is pumped to the display and allotted interval sensible by pumps.

Paste is transferred to the engraved curler by coloration furnishing curler.

Up to 24 hues ought to per opportunity also be printed yet 8-10 are printed effortlessly.

Even 16 engraved curler ought to per opportunity also be used for multiple hues of sample solely four-6.

Can be printed woven and knitted cloth.

Can be printed woven and tricot cloth.

The important gear of printing is rotary display.

The important gear of printing is engraved curler.

Design ought to per opportunity also be reworked at as soon as.

More time required for converting of sample.

Engraving expenses a bit diminish than copper curler.

Engraving expenses is more valuable.

Setting up time diminish.

Setting up time more valuable.

Production rate-high.

Production rate medium.

Pressure of fabric low.

Pressure of fabric high.

Skillness required by the operator is low.

Skillness required by the operator is high.

Color utilized is more adaptable.

Color utilized is less so much on a steady basis.

You ought to per opportunity also like:

20 Key Differences between Dyeing and Printing

Printing Paste Ingredients and their Functions

Fully Automatic Flat Screen Printing Machine

What is Discharge Printing? | Discharge Printing Methods

Styles of Printing or Printing Styles

Different Types of Printing on Denim Fabric

Advertisement