Comber is a private computer within of which fiber are combed and the action is is brought up as combing. The straightening and parallelization of fibers and the removal of transient fibers and impurities by utilising utilizing combs, knives, brushes and rollers. One combed sliver is synthetic from eight lap.

Fig: Comber private computer

Objects of combing:

To eradicate a chose interval of transient fiber so as that combed sliver is made by utilising extra long fiber.

To eradicate neps and worldwide materials from carded fiber.

To make fiber swiftly and parallel.

Necessity of combing:

To produce finer or extra green yarn.

To produce uniform yarn.

To produce less thick, skinny and hairiness yarn.

Why combing is imperative for finer yarn?

For finer yarn count number, high draft is required then again draft irregularity for presence of transient fiber. After combing transient loose product is ready for greater draft.

Longer fibers are finer than transient fibers.after combing greater count number isthat you'll suppose of to shield minimal no fiber in yarn dia. Ring spinning system a minimal of 60-sixty five no of fiber. Rotor spinning system extra than 80 no of fiber. If interval augment then yarn dia lower.

Long fiber yarn has less hairiness then again extra luster.

Combing is imperative for extra green yarn appear and regularity.

Less twist for finer yarn then again extra twist required in existing of transient fiber.

Contribution of combing to yarn prime high quality:

Improve the spinning significance of fiber.

Better twist distribution, which spice up the flexibleness of yarn.

Improve uniformity, clean and lusture of yarn.

Reduce yarn hairiness and imperfection.

Produce transient trash loose transparent yarn.

Combing cycle:

Combing operation is completed by utilising cycle shrewd. Combing cycle or sequence of combing is indicate less than:

Lap feeding by utilising feed curler

Lap nipping by utilising the nipper

Combing by utilising the cylinder

Nipper opening and forwarding

Detaching curler backward action

Piecing

Combing by utilising the peak comb

Detaching curler forward action

Starting a new cycle

Cleaning of cylinder comb

Fig: Combing operation

Noil: Noil is is brought up as the wastage of comber private computer, which is constitute of transient fiber, neps and impurities.

Degree of combing:

The amount of noil extracted or later of combing, which is expressed in selections is is brought up as diploma of combing. Degree of combing is trusted the transient fiber presence in raw cotton, prime high quality of yarn and conclude makes use of of yarn.

Types of combing:

Types of combing on the premise of diploma of combing:

Half combing------------- upto 8% noil extraction

Ordinary combing --------- nine-15% noil extraction

Full combing ----------------- 16-18% noil extraction

Double combing ------------- 19-25% noil extraction

Factors of diploma of combing or noil extraction:

1. Amount of transient fiber in the raw cotton: If the row cotton entails a limiteless amount of transient fiber, a high diploma of combing turns into imperative to get a high amount of noil extraction for brilliant prime high quality yarn.

2. Production prime high quality: For brilliant prime high quality of yarn, the volume of noil have got to be existing in limited variety then again passing if number of noil, now now not learned of brilliant prime high quality yarn. Up to 25% noil, yarn power, lusture are steadily elevated then again after that now now not augment of power.

three. Production can significance: Higher diploma of combing acquired rid of greater noil% wherein production turns into gradual at an physical time the production can significance flip out to be greater.

Main atmosphere aspects of comber:

Nipper and detaching curler.

Cylinder needle and nipper

Top comber gauge

Brush atmosphere

Effect of comber atmosphere on noil extraction:

1. Effect of detaching atmosphere: The distance between the peak-prime high quality fringe of the feed plate and the nip of the detaching curler with regards to atmosphere for an physical staple interval will lessen back the noil extraction% and vice versa. When the ambience is wider for the exact form.

2. Effect of peak comb atmosphere: The amount of waste extracted also might quite often quite often also be adjusted by utilising converting the place of peak comb, combing operation is also right and the noil extraction is also high. If that's set to the nippers, the waste extraction is also lower.

Characteristics of combed sliver:

Most of the fibers are long in combed sliver.

Fibers of combed sliver are swiftly and parallel of sliver axis.

Sliver has uniform weight according to unit interval.

No projected fiber at the floor of sliver.

Sliver is clean and current.

Sliver is loose from trash and neps.

Efficiency of comber: 80-90%

Draft imperative at comber: 6-12

Production according to comber: 50-100 fifty Kg/hr/according to source

Distinguish between card, draw and combed sliver:

Sliver form and residences

Fiber arrangement in sliver

Disoriented

Straight, parallel and oriented

Straight, parallel and oriented

Neps and trash

Depend on card or combed sliver

Short fiber

Depend on card or combed sliver

Sliver fineness (Ne)

You might quite often quite often also like:

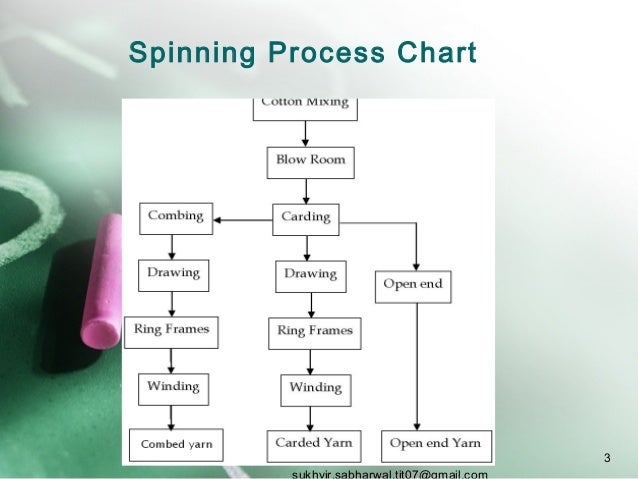

Yarn Manufacturing Process

Analysis of Textile Filament Yarn and the Yarn Size System

Properties of Cotton Yarn

How to Identify the Substance of Textile Yarn

Yarn Consumption Calculation for Woven Fabric

Yarn Faults in Spinning | Common Types of Yarn Faults

Yarn Count Numbering System and Conversions

Yarn Count Measurement System

Advertisement